Engineering and process for sustainable economy

We believe in circular economy. Our products are made for companies who think this way and want to show it to the world.

We believe in circular economy. Our products are made for companies who think this way and want to show it to the world.

We base our solutions on patented technology for thermal treatment of the bulk products: Spirajoule®

We base our solutions on patented technology for thermal treatment of the bulk products: Spirajoule®

We deliver customised solutions to valorise your resources just at the place they are needed

We deliver customised solutions to valorise your resources just at the place they are needed

Since 30 years, we design and deliver equipment to create value from your waste and residues.

Since 30 years, we design and deliver equipment to create value from your waste and residues.

Company for creating ecotechnologies

ETIA (Evaluation Technologique, Ingénierie et Applications) is a French engineering group specialized in ecotechnologies: innovation, equipment, and processes for continuous thermal treatment.

Our focus is in the engineering of circular economy products. Our company designs and provides plants for processing biomass, food products and industry residues, which are widespread in the sectors of environment, agro-food and energy.

Continuous innovation

Besides the industrial activity, ETIA is also involved in many research programs working in close collaboration with academic and industrial partners in order to develop new technologies and new products in the fields of sustainable development and circular economy.

Industrially proven solutions

Since almost 30 years, we design and provide patented solutions for industrial applications. From thermal treatment components, up to complete turnkey plants, we deliver durable and easy to use products for the circular economy.

Complete valorization process

We deliver turnkey plants tailored to the demand of the industry. By understanding the requirements and market background of our Customers, we are able to deliver a complete process for the valorization of residues and waste.

Innovation and expertise

With our dedicated subsidiaries, we offer complete research and expertise for the industry, including expertizes, feasibility studies, research on bio-based products a well as process automation and robotics.

Recognised for innovative approach.

Innovation, durable solutions and reliability. These are the fundamental values brought by ETIA. Values derived from continuous and extensive research. The industry can ask for everything: drying, cooling, steam sterilization, pasteurization, extraction, toasting, cooking but also roasting, pyrolysis, gasification, ozone treatment. ETIA takes care of all.

BPI (Banque publique d’investissement) France

News from ETIA Group

ETIA propose une technologie prometteuse pour valoriser les déchets plastiques non recyclables

Chaque année, environ 460 millions de tonnes de plastique sont produits, faisant du plastique le troisième matériau le plus fabriqué au monde, derrière le ciment et l’acier. Aujourd’hui, 81% des …

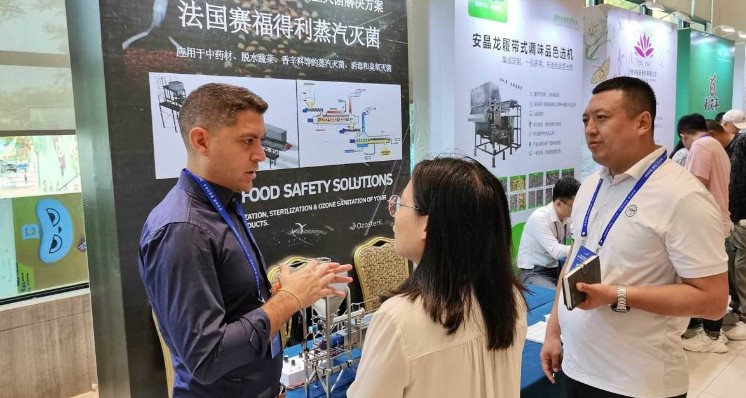

Vow ASA Subsidiary, Etia, Secures Contract with Qingdao Deeshenghengxin Food Company

October 21st, 2023 We are thrilled to announce that our subsidiary, Etia, has recently entered into a contract with Qingdao Deeshenghengxin Food Company. The agreement entails the delivery of a …

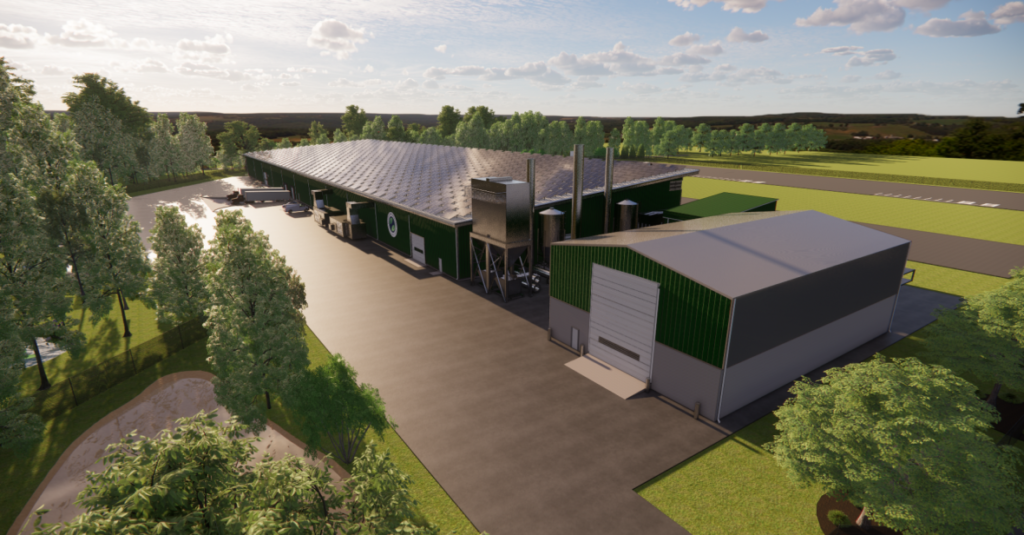

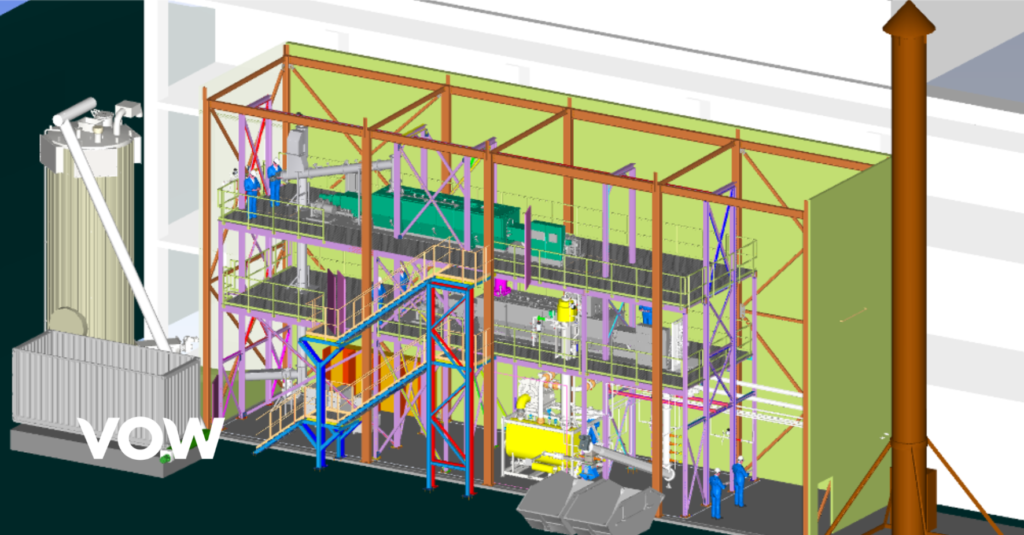

Major milestone reached in Vow’s breakthrough US project

July 17th, 2023 In May last year, Vow ASA agreed to deliver a complete biochar and renewable energy system valued at USD 27 million in the US. The project has …

Vow ASA: Additional 2,500-tonnes production facility at Follum to be transferred to Vow Green Metals

Vow ASA (« Vow » or « the Company ») is in discussions with Vow Green Metals about the potential sale of a 2,500 tonnes biocarbon production facility at Follum, Norway, featuring a Biogreen …

Vow ASA: Vow and ETEL team up for recycling of end-of-life tyres

Vow ASA has teamed up with European Tyre Enterprise Ltd. (ETEL), to deploy Vow’s advanced technology in a complete solution to convert end-of-life tires to valuable raw material and renewable …

Vow ASA: Vow awarded three Safesteril contracts

Vow ASA (OSE: VOW) subsidiary ETIA Ecotechnologies (ETIA) has received orders for a total of three Safesteril food safety systems so far in the first quarter. The combined value of …